Press-fit-Tooling

Customised for your application

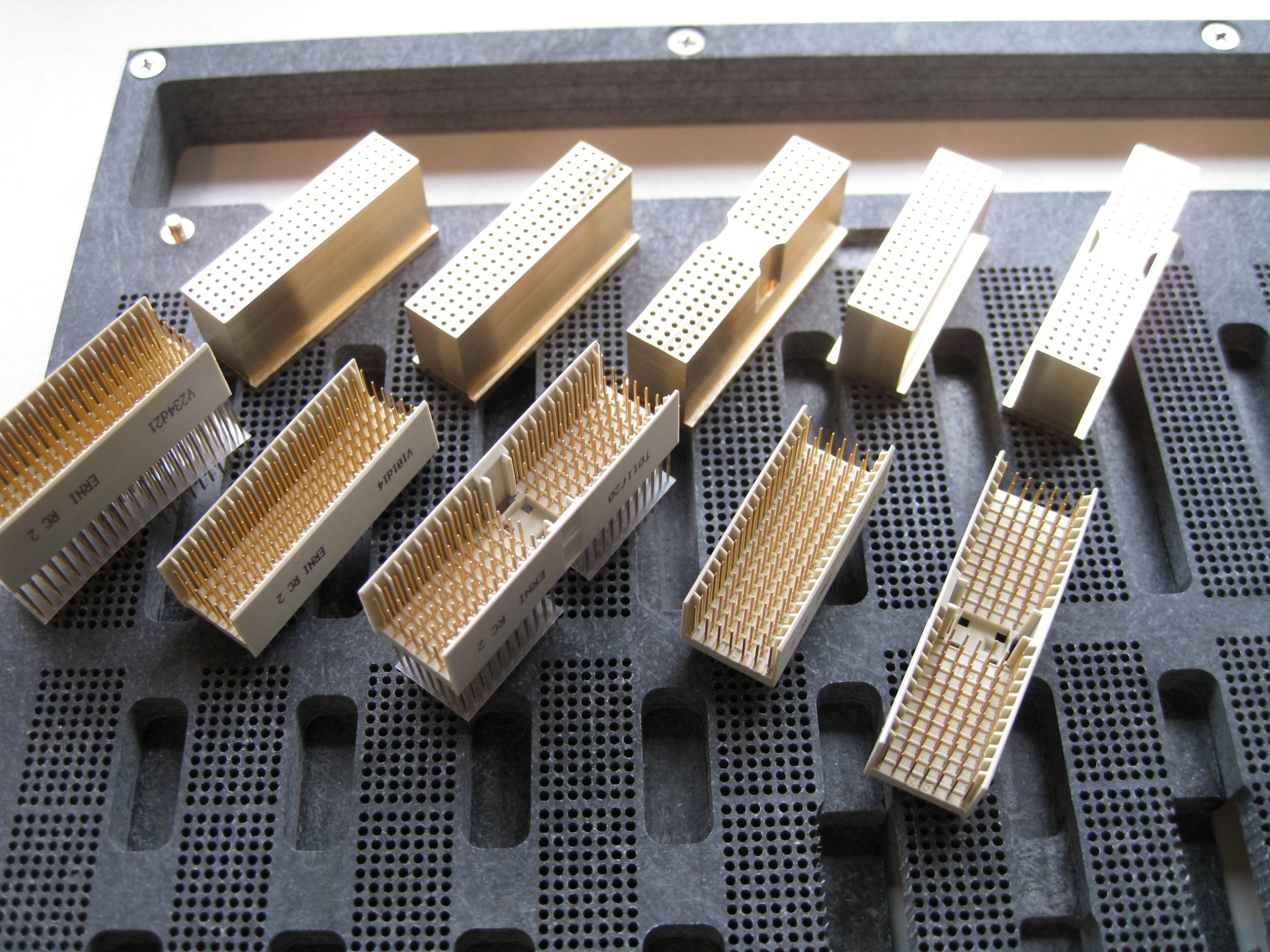

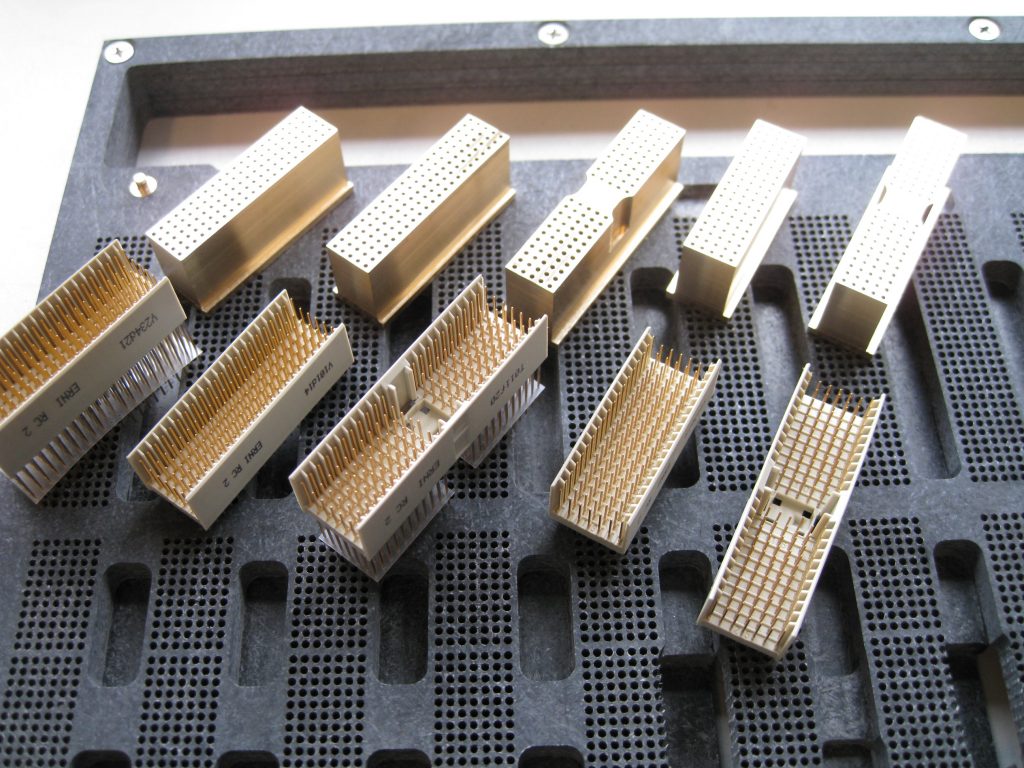

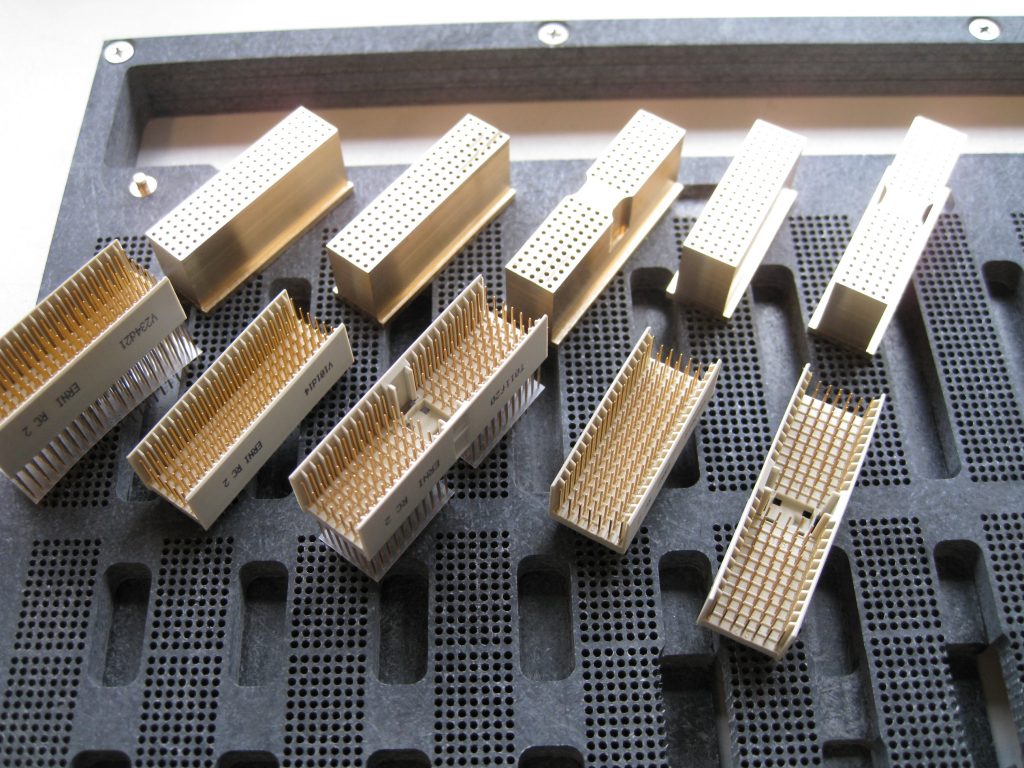

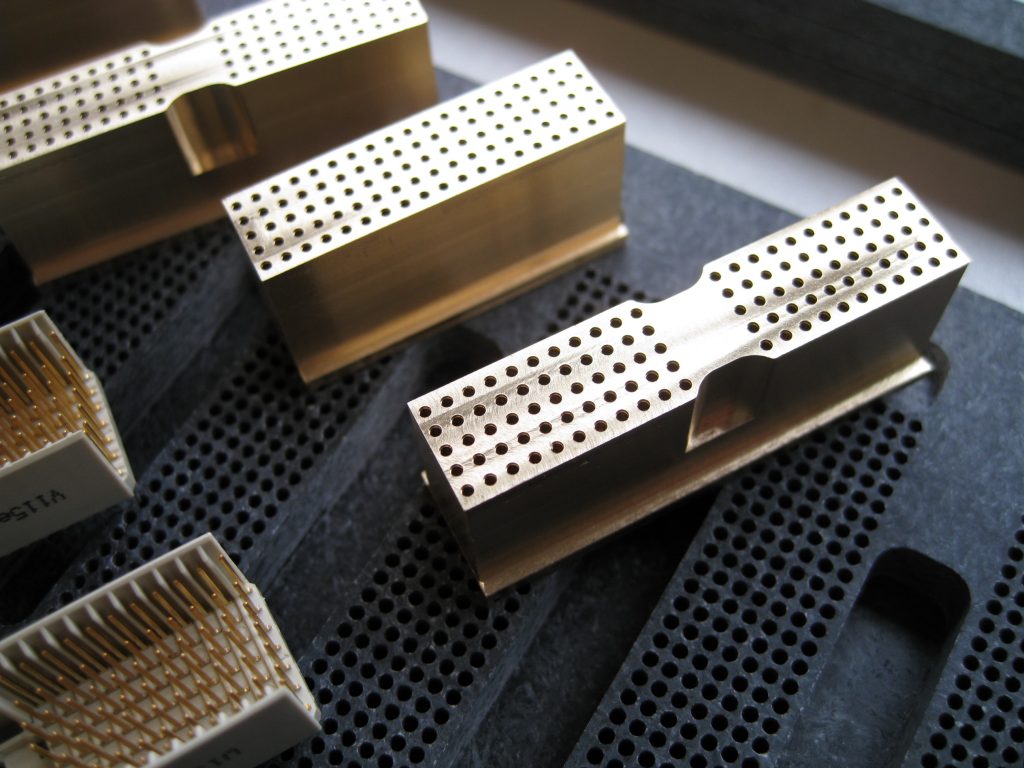

The electronics industry is increasingly using Press-fit applications. Through-hole components are increasingly being converted to press-fit solutions. A press is used to push the press-fit connectors into a PCB. This is done in our ESD-safe room. The customised press-fit tooling is used in this process to support the work. The tooling is made of aluminium, brass, stainless steel and ESD-safe composite materials.

Advantages of our Pressfit Tooling:

- Good support and cut-outs for components

- Centring of the PCB by means of dowel pins

- Set consists of a base plate and top-compression tooling

- Pressing tool made to measure

- Work is carried out in an ESD-safe room

- Prevents damage to components on the printed circuit boards

- CNC-manufactured based on PCB information

Looking for more technical information about our Pressfit Tooling?